Satin 3 is the most durable coating currently available under the Satin brand. Satin 3 offers increased performance in both scratch resistance and durability. Formed of 7 layers, this anti-reflective coating is formulated to provide optimum protection from scratches whilst maintaining good lens aesthetics. This coating is ideal for wearers who demand the most durability from their lenses, or who find that their lenses become scratched often.

Exposure to UV rays from the sun causes damage to the human eye, even when wearing spectacles. Many lenses offer protection from UV rays passing through the front surface of the lens, but some may neglect the dangers posed to the eye through back surface UV reflection. Satin 3 builds on the strengths of Satin Plus UV, providing back surface protection from reflected UV rays, and combines this UV protection technology with enhanced scratch protection and durability to give a lens that is perfect for every day wear both in and outdoors.

Satin 3 provides excellent protection from UV light, as the coating is applied to both the front and back surface of the lens. This provides protection from both the transmission of UV rays through the front surface, and reflection of UV rays from the back surface of the lens.

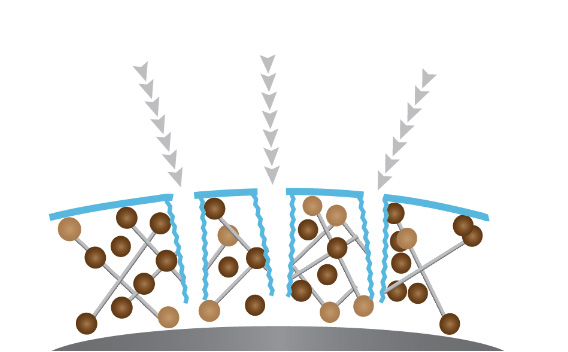

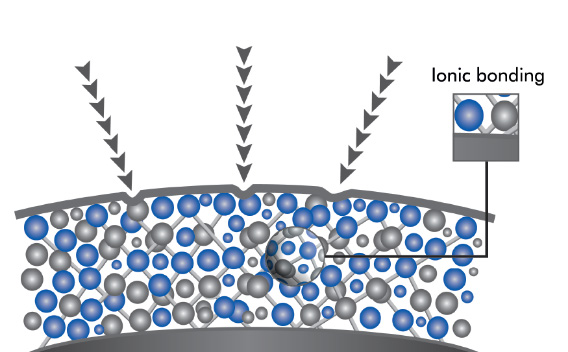

As well as the enhanced coating durability and UV protection from both lens surfaces, Satin 3 provides all of the superb benefits associated with the Satin coatings range. The Enhanced Scratch Guard Technology of Satin coatings has a good adhesive property, which makes the coating hard and provides unparalleled scratch resistance when applied to the surface of the lens. The formula is flexible and created using ionic bonding to help prevent cracking and peeling of the coating. This is further enhanced in Satin 3 to give our strongest coating to date. With an ordinary AR coated lens, coating cracks can appear due to the coating breaking down, and the molecules splitting apart from their bonds when subjected to external pressure. The bonds within the Satin 3 coating are stronger, and more able to withstand these pressures than regular AR coatings. Satin 3 is a hard multi coating (HMC), and provides a multitude of benefits over a regular AR coating.

Most modern lenses are made from either plastic or polycarbonate. These materials provide many benefits over more traditional glass lenses, but the material itself is softer and therefore more susceptible to scratches. The application of a high quality Satin coating will help protect the lenses from scratches through every day wear and tear. The coating is also very easy to clean, ensuring that keeping the lenses in their best possible condition is simple and straightforward.

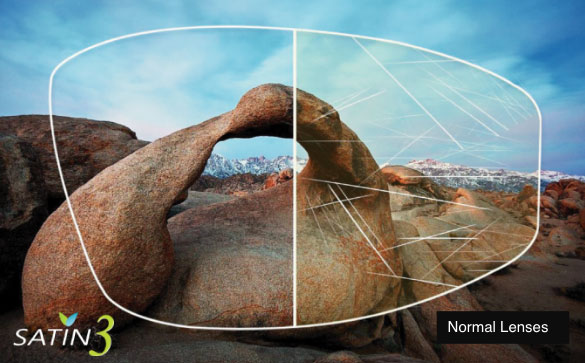

Ordinary lens

Satin coated lens

ES Guard technology also has an index matching property that makes the application of Satin coatings unique to each lens index, and also provides tint stability for all materials. The coating process is carried out at a controlled temperature in a state of the art facility to achieve maximum scratch resistance properties on the lens

The anti-reflection properties of Satin coatings improve the aesthetics of the lenses, as well as the visual clarity and comfort for the wearer. Anti reflective coatings are especially recommended for use with polycarbonate and high index lenses, as the material properties can cause more reflections than regular plastic lenses.

Water droplets will quickly slide off the lens surface producing the Lotus effect thanks to the LQ Technology of Satin coated lens. With the help of LQ Technology, the contact angle increases to more than 110 degrees, ensuring excellent hydrophobic properties.

SD (smudge & dust) Guard Technology is a protective layer applied to Satin coated lenses that, guards against dust particles and oil. This layer makes the lens oleophobic, preventing oil and dirt from penetrating into the lens material, thus making the lens smudge resistant. It also reduces the accumulation of frictional static charge by neutralising the lens surface, in turn reducing dust accumulation making the lenses almost dust free.